The declared goal of Operational Excellence can only be achieved if leading tools and methods are applied in everyday work. As a sharing provider, you may be able to leverage already proven corporate practices. Some practices can be integrated without turning the existing corporate structure upside down and for others it requires at the very least a changed mindset of all employees. In this article, we present three basic approaches that can assist you on the path to Operational Excellence.

Why the Effort?

Not every organization follows a particular management philosophy in its work processes and internal collaboration. Instead, processes are often based on individual decisions and routines. In making the decision to use a specific management philosophy, rethinking and restructuring is necessary. If this effort is pursued consistently, it is rewarding and worthwhile.

Although different approaches have different emphases, they share fundamental goals and effects. These include:

Starting Is Half The Battle

The first step is the most difficult in most change management processes. Start by appointing the responsible team members who will take the lead on restructuring as well as who will be the first to attend seminars and training on the various corporate practices.

Follow the guiding principle that organizational development is a marathon, not a sprint. It doesn't matter how big your steps are, it only matters that you take some. Change and optimize your processes one step at a time and include all employees through regular feedback evaluations.

Consolidated Knowledge for Take Away

This guide offers an easy introduction, extensive knowledge, best practices, tips & tricks. In 43 pages, you'll learn how to perform better with your team and add value to your offerings.

Continuous Improvement Process (Kaizen)

As the name suggests, the Continuous Improvement Process (CIP) is a constant effort to improve one's own service or work processes. In contrast to innovation, where development occurs rapidly, changes within the framework of the CIP happen in continuous small steps.

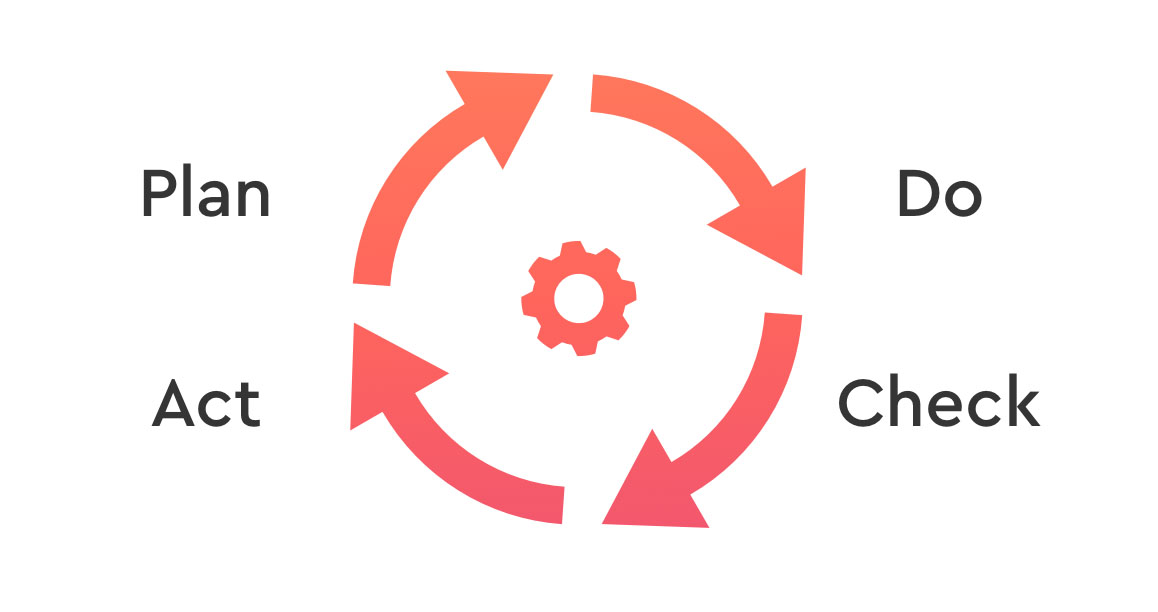

PDCA-Cycle

An important tool in the Continuous Improvement Process is the PDCA-Cycle, also known as the Deming- or Shewhart-Circle based on the names of its inventors. PDCA stands for the four following steps:

Plan: Determine goals and measures to achieve them

Do: Implement the measures

Check: Assess whether the measures have led to desired goals

Act: Depending on the result, maintain planned measures or make adjustments

This cycle is run through again and again. In this way, processes and products are optimized and improved in small, continuous steps.

Lean Management

Lean Management also originated from the Japanese automotive industry and is based on Kaizen. Starting as a method for "Lean Production", it is now applied as a holistic management philosophy in all areas of a company.

Lean Management is often understood as solely a method for cost savings. This understanding, however, does not do it justice, as another central aspect is overlooked. Customer orientation is just as important to Lean Management and this means every process or sub-process should be aligned to the needs of the users.

Examples of waste are:

Overproduction (e.g., a fleet that is too large and not optimally used to capacity).

Long waiting times (e.g. for cleaning/maintenance or answering a user request)

Errors (e.g. booking a vehicle that is currently not available)

Unused creativity (e.g. lack of cross-team exchange)

In order to minimize such types of waste in the future, the first step is to determine the relevant figures, data and facts. Then, with the involvement of all employees, seek out the methods and possibilities which can make processes more efficient. Lean Management is especially applicable to recurring processes.

Like Operational Excellence, it describes a philosophy or corporate culture rather than a specific method. Instead, processes and tools based on Lean Management are used. These are, for example, 5S, Kanban, Just in Time, Right First Time, Poka Yoke, etc. The problem at hand determines which of these processes can be used.

The path to shared mobility success ⟶

Lean Management agrees that standardization is not always applicable as there is no one right tool for every business situation.

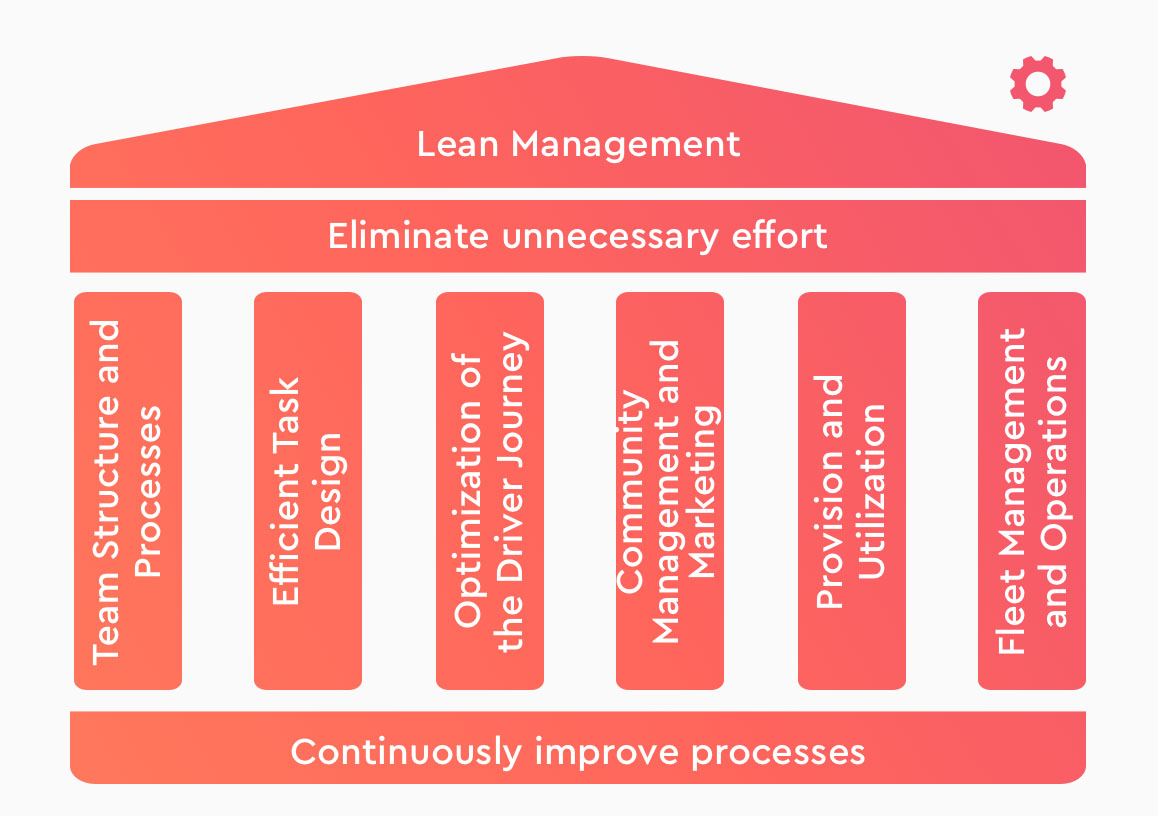

6 Pillars of Lean Management for Sharing Provider

In Shared Mobility, Lean Management is based on six pillars, which can be used as starting points for the effort to optimize processes and in turn avoid waste.

Agile Processes

Today's corporate environment is subject to major changes and fluctuations due to digitalization. The mobility industry is also subject to these changes. In order to be able to react more flexibly, proactively and adaptively, more and more organizations are integrating agile working methods into their corporate management.

Further reading tips about Operational Excellence ⟶

There is no correct answer to the question of whether an organization should use agile or classic methods for project management - the influence of dynamic developments is too varied. Agile is rather a supplement to classic process management than a replacement for it. As a sharing provider, take a close look at which areas of your business can benefit from agile process management and which you can continue to run classic processes.

SCRUM Method

Originally, SCRUM came from software development, but it is now used in project management. The method provides a framework in which a team can solve complex tasks and requirements and deliver the best possible result.

Relevant terms in SCRUM

Many Paths Lead to Excellence

Which of the management approaches is easiest for your organization to integrate and leads to the desired results is difficult to say. The methods presented are not mutually exclusive and can be combined as necessary. You may have different areas of your organization which require different tools.

When choosing the appropriate method(s), take into account the structural requirements of your organization, your current weaknesses, the needs of your customers and the situation in the local mobility market. There is not only one path to Operational Excellence, but many different ones - find the path that best suits you.