Do you know what is meant by the term Operational Excellence? Simply put, it is about optimizing internal processes and workflows. In this article, you will learn why it is worth taking a closer look at Operational Excellence and how it is more of a vision than an achievable state.

Why it Pays to Focus on Process Optimization

The shared mobility market continues to grow: Global sales growth of around 9% per year is expected up to 2026 (source: Statista). Part of this growth includes the fact that more and more shared mobility providers are entering the market and that there is a high level of competition, especially in large cities. Shared mobility offerings compete not only with each other, but also with private vehicles and public transport.

As a result of this competitive pressure, not all sharing providers are able to operate profitably and establish themselves on the local market, despite the continued demand. A company's own business model and product must be regularly put to the test and tailored to customer needs. But perhaps the most important key to success is hidden in the core of one's own organization: in the internal processes and workflows.

A study by the Harvard Business Review concluded that in terms of productivity, sales growth and profits, the companies that optimize their management methods and processes have a clear advantage over those that do not. They also excel in higher expansion rates and longevity.

Harvard Business Review: Why Do We Undervalue Competent Management? →

Striving for process optimization and Operational Excellence should therefore be a high priority. Decision makers should not be deterred by the additional effort required at the beginning to introduce an Operational Excellence strategy and implement the associated changes in the day-to-day organization of work. Especially as an operator of a sharing service you should not be discouraged because the operational tasks required have a direct influence on customer satisfaction. Remember: The more optimized the processes are, the more positive the customer feedback and the greater the long-term success will be.

What Does Operational Excellence Mean?

Do you question existing workflows and strive to operate as efficiently as possible in order to offer your customers a smoothest possible service? Then you may already be striving for Operational Excellence without even knowing it.

Operational Excellence describes a company's focus on continuous improvement of recurring work processes. Regular reflection, observation and internal feedback systems are best used to identify potential areas that need optimization and then initiate appropriate changes. The proclaimed corporate goal is the guiding principle here.

Process optimization brings you a little closer to achieving this goal every day, improves your customer benefits and ensures the company's success. The concept of Operational Excellence does not specify the concrete measures necessary to achieve this. Rather, it is a mindset that influences internal working methods and philosophies.

To strive for operational excellence, you don't have to reinvent the wheel. It is not about developing a whole new service and doing things completely different than competitors. Instead, it is more valuable to do what you already do better than anyone else. It is even sufficient enough if you are the best solely from the point of view of your own target groups. Don't set yourself any mental limits, but be creative when it comes to increasing your own performance and optimizing what you already have.

Compact Knowledge for Take Away

This guide offers an easy introduction, extensive knowledge, best practices, tips & tricks. In 43 pages, you'll learn how to perform better with your team and add value to your offerings.

Download Guide

Is Operational Excellence Measurable?

Operational excellence is not a state that can be achieved, but rather a process in itself. Internal work processes are continuously reviewed and optimized. It is a continuous cycle that shapes actions in the company over the long term.

For this reason, Operational Excellence is difficult to measure. However, in order to obtain information about the current quality of the company's own performance, some key figures can be used as indicators.

By reducing effort and costs and increasing customer satisfaction at the same time, the company's profitability and economic viability are enhanced. Ultimately, the goal of Operational Excellence is also the monetary success of the company - and this can certainly be measured.

Therefore, to regularly review Operational Excellence, the following key performance indicators and metrics are used:

Sales development

Development of booking figures

Number of new registrations

Number of cancellations

Cost development

Customer feedback (e.g. number of complaints)

Employee satisfaction / motivation

Employee efficiency

Best practice tip:

Monitor certain metrics with the help of the MOQO Provider Portal and conduct employee surveys on a regular basis (e.g. quarterly).

What Questions Sharing Providers Should Ask Themselves

It is easy to say that internal workflows and processes are the root of all problems and at the same time the key to long-term success. It is much more difficult to put this insight into practice and anchor Operational Excellence in the mindset of all employees.

However, because shared mobility in particular is an extremely operations-oriented field and is subjected to high competitive pressure, it is worth taking on the challenge of achieving Operational Excellence.

The first step is to identify the status quo and examine it from different angles. The following questions will help you to reflect and gain insight to the possibilities and starting points of outstanding process management.

Are those responsible in your company making a conscious effort to optimize internal work processes?

Are the needs of customers at the center of all efforts? Are feedback and suggestions for improvement accepted and implemented?

Are internal processes clearly defined and transparent? Is there a clear distribution of tasks? What happens if a team member is absent?

Is there a willingness in your team to rethink and change already established processes?

How much time do you spend daily on operational tasks such as processing user requests, managing your fleet or processing payment? How quickly do you respond to user requests?

What are the common issues that come up? What is required to fix them and how much time does this take? What would you need to do to prevent these problems from occurring in the first place?

What do you want to achieve with your sharing service?

What success metrics do you measure on a regular basis? How much do you base decisions on these?

Move From Reacting to Flowing Efficiently

As long as sharing providers do not have clearly defined processes and responsibilities, they are in a constant state of reacting to external circumstances and unforeseen events. A customer has booking issues - you find time and respond as soon as you see the request. A car breaks down - you put it in maintenance mode and take it to the repair shop. You receive a complaint about the cleanliness of a vehicle - you arrange for it to be cleaned.

It is more efficient to set standardized procedures for all recurring and possible events and then optimize them until the effort is minimal and the effect has become maximum. In most cases, the pursuit of Operational Excellence doesn’t mean new tasks are added; on the contrary, processes are progressively simplified and reduced until only what is necessary.

Methods for Process Optimization in Practice ⟶

The more you are able to stay ahead of predictable events and implement efficient workflows relating to maintenance, cleanliness, charging statuses, placement of vehicles, etc., the less you have to operate in reaction mode. Identify critical points in the customer journey before they become an issue resulting in customer complaints, for example.

As addressed earlier, this is an ongoing process in itself. You will never be able to mark this as "done", but rather you’ll base the entire business strategy on optimizing all processes and workflows. It is recommended to initially focus on single (sub-)processes and revise them step by step.

The following approaches and tips will support you on your path to Operational Excellence:

Streamline your processes and make them scalable

Look for as many automations and intelligent software solutions as possible

Prioritize your tasks

Define clear responsibilities

Regularly collect customer feedback and measure customer satisfaction

Keep an eye on your key performance indicators

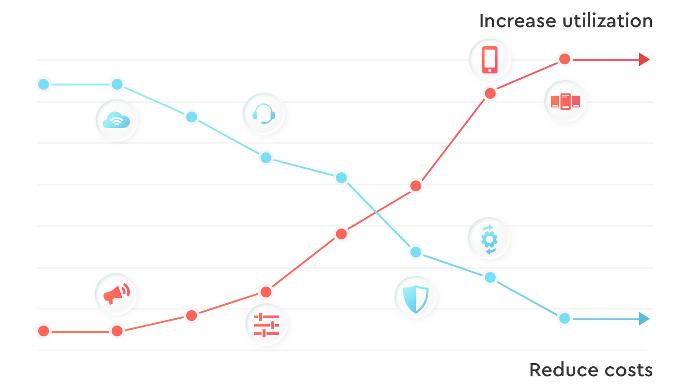

Competitive Advantages Gained Through Operational Excellence

Ultimately, neither the number of your vehicles on the road nor the sum of your daily bookings will determine your long-term success. Rather, it is how your internal processes are optimized. Through maximum efficiency, you’ll minimize costs and at the same time make your customers happier than your competitors do.

Make the decision in your organization to henceforward be excellent - and act accordingly. This includes everyone involved: from the management team to the responsible employees to the contracted service providers.

The tools and methods you use are of secondary importance. What is important above all is the will and discipline to align the company with a consistent strategy for Operational Excellence.